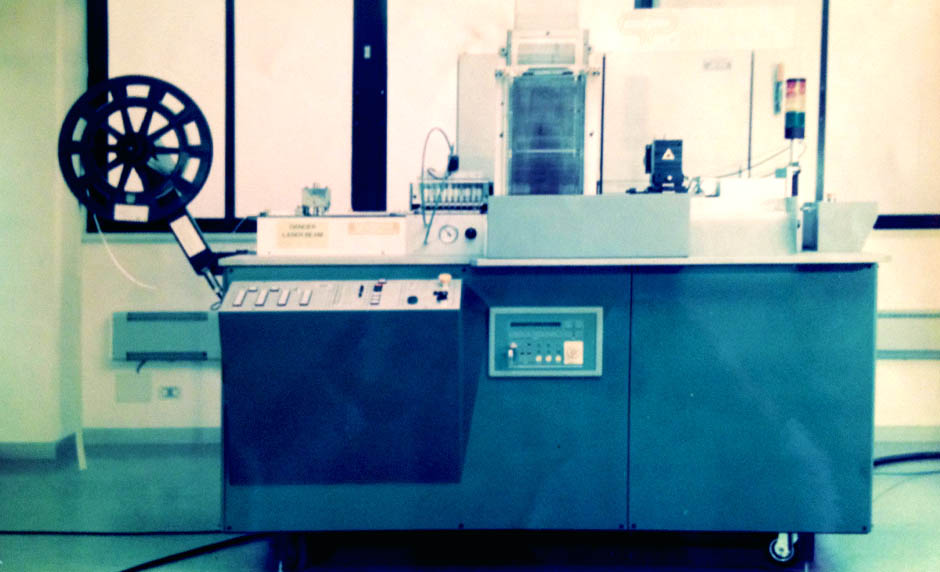

S108

Highly integrated laser welding machine for tantalum capacitor type "A, B, C, D and E flat". The original laser welding process has been set by GP.synergy in 1987 and now used by the most important manufacturers in the world. The machine is fed by double row lead-frame in reel. The anodes of tantalum capacitors are fed in racks. The final product is a capacitor welded by laser on the lead-frame after applying a silver adhesive deposit below the anode and related curing.

- Cadence:more than 24.000 capacitors per hour

Size

length: 240 cm

width: 120 cm

height: 175 cm

Technologies

- Laser cutting and welding based on a unique GP.synergy process

- Lead frame cutting and forming

- Silver Solder paste deposit

- Fast product change available