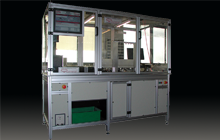

M503

Singulating and wire&contour inspection machine for Ceramic DCB (Direct Copper Bonding) modules from MasterCard. The cards are supplied to the machine in magazines. Each singulated and vision inspected module is inserted into output RFID coded Trays. Rejects are placed into RFID coded blisters. Trays with good parts are delivered In-Line to the next machine. The machine is fully programmable to execute the complete cycle starting from product recipe. A sophisticated "Touch screen" operator panel based on PC allows the fully programmability for a variety of products as well the control of each machine alarm. Complete connection with Factory Oracle data base allows fully traceability for each single produced device. An included FIFO Buffer for trays reduces impact of down-time of next machines of the line. .

- Cadence: better than 5 second for piece

Size

length: 210 cm

width: 96 cm

height: 185 cm

Technologies

- Singulation of Ceramic substrates

- "Touch screen" operator panel based on PC

- Wire conformity AOI

- Edges conformity after singulation AOI

- Full Traceability of each single device of the Master card with Factory Oracle Data Base

- Full programmability of each station

- RFID coded Trays and Blister handling

- Matrix and bar code readout